Categories

New products

-

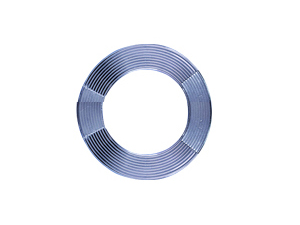

Standard Spiral Wound Gasket

Kaxite® Standard Spiral Wound Gasket here,Manufacture Standard Spiral Wound Gasket,Standard Spiral Wound Gasket for you, high quality and reasonable price.

-

Lens Ring Joint Gasket

Kaxite® Lens Ring Joint Gasket here,Manufacture Lens Ring Joint Gasket,Lens Ring Joint Gasket for you, high quality and reasonable price.

-

Double Jacket Gasket

Kaxite® Double Jacket Gasket here,Manufacture Double Jacket Gasket,Double Jacket Gasket for you, high quality and reasonable price.

-

Corrugated Gaskets

Kaxite® Corrugated Gaskets here,Manufacture Corrugated Gaskets,Corrugated Gaskets for you, high quality and reasonable price.

-

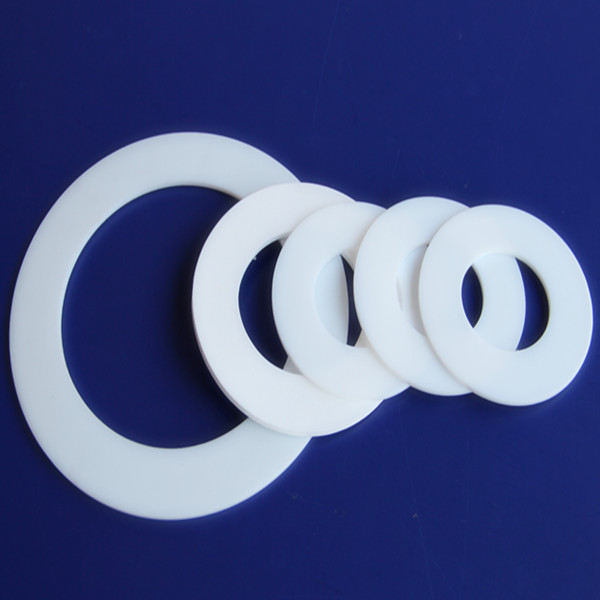

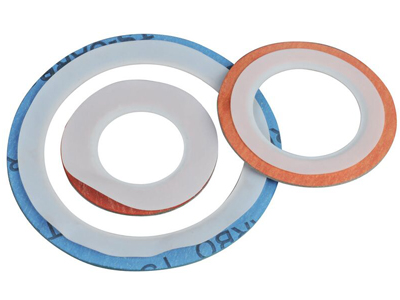

PTFE Envelope Gasket

Kaxite® PTFE Envelope Gasket here,Manufacture PTFE Envelope Gasket,PTFE Envelope Gasket for you, high quality and reasonable price.

-

Double-jacketed gaskets

Double-jacketed gaskets are another combination of filler material and metallic materials. In this application, a tube with ends that resemble a "C" is made of the metal with an additional piece made to fit inside of the "C" making the tube thickest at the meeting points.

-

Constant seating stress gaskets

The constant seating stress gasket consists of two components; a solid carrier ring of a suitable material, such as stainless steel, and two sealing elements of some compressible material installed within two opposing channels, one channel on either side of the carrier ring.

-

Spiral-wound gaskets

Spiral-wound gaskets comprise a mix of metallic and filler material. Generally, the gasket has a metal (normally carbon rich or stainless steel) wound outwards in a circular spiral (other shapes are possible) with the filler material (generally a flexible graphite) wound in the same manner but starting from the opposing side.

-

Solid material gaskets

The idea behind solid material is to use metals which cannot be punched out of sheets but are still cheap to produce. These gaskets generally have a much higher level of quality control than sheet gaskets and generally can withstand much higher temperatures and pressures.

-

Sheet gaskets

The premise is simple in that a sheet of material has the gasket shape "punched out" of it. This leads to a very crude, fast and cheap gasket. In previous times the material was compressed asbestos, but in modern times a fibrous material such as high temp graphite is used.

-

Gasket Properties

Gaskets are normally made from a flat material, a sheet such as paper, rubber, silicone, metal, cork, felt, neoprene, nitrile rubber, fiberglass, polytetrafluoroethylene (otherwise known as PTFE or Teflon) or a plastic polymer (such as polychlorotrifluoroethylene).

-

Gasket

A gasket is a mechanical seal which fills the space between two or more mating surfaces, generally to prevent leakage from or into the joined objects while under compression.