Categories

New products

-

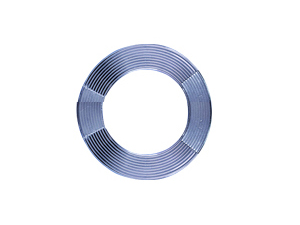

Standard Spiral Wound Gasket

Kaxite® Standard Spiral Wound Gasket here,Manufacture Standard Spiral Wound Gasket,Standard Spiral Wound Gasket for you, high quality and reasonable price.

-

Lens Ring Joint Gasket

Kaxite® Lens Ring Joint Gasket here,Manufacture Lens Ring Joint Gasket,Lens Ring Joint Gasket for you, high quality and reasonable price.

-

Double Jacket Gasket

Kaxite® Double Jacket Gasket here,Manufacture Double Jacket Gasket,Double Jacket Gasket for you, high quality and reasonable price.

-

Corrugated Gaskets

Kaxite® Corrugated Gaskets here,Manufacture Corrugated Gaskets,Corrugated Gaskets for you, high quality and reasonable price.

-

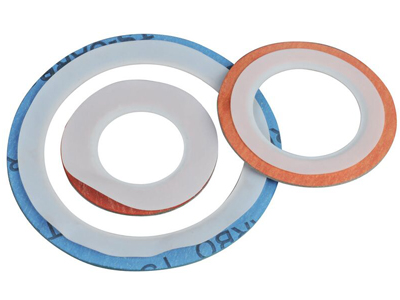

PTFE Envelope Gasket

Kaxite® PTFE Envelope Gasket here,Manufacture PTFE Envelope Gasket,PTFE Envelope Gasket for you, high quality and reasonable price.

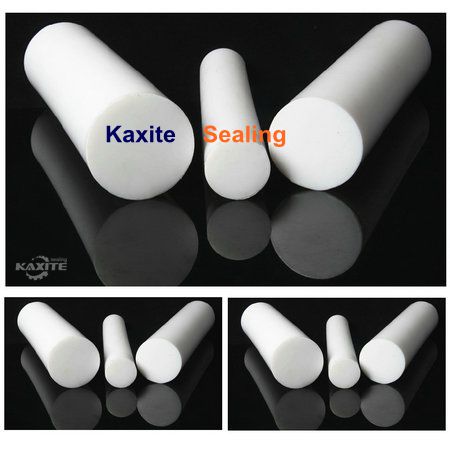

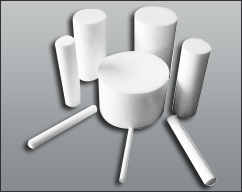

Molded PTFE Rods

PTFE rods may efficiently work at the temperature -200 oC- +250 oC. So it is an ideal element for the food industry. It consists of the best dielectric property. Due to this property, the rods are used in electrical and electronics industries

PTFE Teflon Round Rod Bar

We are one of the leading supplier and exporter of the ptfe rods in China. The ptfe rods are acknowledged for their property of very low coefficient for the friction. So the ptfe rods are self-greasing up rods.

PTFE rods may efficiently work at the temperature -200 oC to +250oC. So it is an ideal element for the food industry. It consists of the best dielectric property. Due to this property, the rods are used in electrical and electronics industries.

• Self lubricant

• High thermal resistance

• Chemically inert

• Easy installation

• Good dielectric property

• Anti friction

Usage

• In medical components

• In electrical and electronic parts.

• For manufacturing of gaskets

• For seals and bearings

• For food processing.

• For insulators.

|

PTFE Rod |

||

|

|

Standard Size: 25mm to 500mm

Length: 300mm

Grade: Virgin & All Filled Grades |

|

|

|

|

|

PTFE Extruded Rod |

||

|

|

Standard Size: 5mm Tto 200mm

Length: 900mm/1000mm

Grade: Virgin & All Filled Grades

|

|

|

|

|

Technical Data:

|

Properties |

Unit |

Result |

Standard Range |

|

BULK density |

gm/1 ASTM D 4894 |

476 |

450-500 |

|

Tensile strength |

MPa ASTM D 4984 |

32.7 |

210-350 |

|

Specific Gravity |

ASTM D792 |

2.14 |

2.1-2.2. |

|

Working Temp |

oC |

250 |

250 |

|

Hardness |

ASTM D 4894 |

58 |

52-58 |

|

Elongation |

% ASTM D 4894 |

286 |

250-400 |

|

Shrinkage |

ASTM-D-570 |

0% |

0% |