Categories

New products

-

Standard Spiral Wound Gasket

Kaxite® Standard Spiral Wound Gasket here,Manufacture Standard Spiral Wound Gasket,Standard Spiral Wound Gasket for you, high quality and reasonable price.

-

Lens Ring Joint Gasket

Kaxite® Lens Ring Joint Gasket here,Manufacture Lens Ring Joint Gasket,Lens Ring Joint Gasket for you, high quality and reasonable price.

-

Double Jacket Gasket

Kaxite® Double Jacket Gasket here,Manufacture Double Jacket Gasket,Double Jacket Gasket for you, high quality and reasonable price.

-

Corrugated Gaskets

Kaxite® Corrugated Gaskets here,Manufacture Corrugated Gaskets,Corrugated Gaskets for you, high quality and reasonable price.

-

PTFE Envelope Gasket

Kaxite® PTFE Envelope Gasket here,Manufacture PTFE Envelope Gasket,PTFE Envelope Gasket for you, high quality and reasonable price.

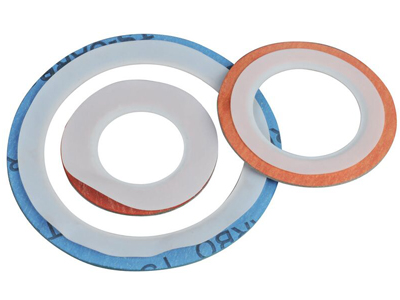

EPDM Flat Gasket Stub Flanges

Rubber O Rings are designed to be seated in a groove and compressed during assembly between two or more parts, creating as a seal at the interface. O-rings are one of the most common seals used in machine design. They are easy to make, reliable and have simple mounting requirements.

Description

O-rings are designed to be a seated in a groove and compressed during assembly between two or more parts, creating a seal at the interface. It is one of the most common seals used in machine design. They are inexpensive and easy to make, reliable, and have simple mounting requirements. They can seal thousands of psi pressure.

O Ring material explanation

| Name | NBR(R) | SI(S) | VITON(V) | EPDM(E) | CR(C) | PTFE(T) | PU | ACR(A) |

| The nature of resisting ozone | X |

|

|

|

|

|

|

|

| The nature of resisting heat |

|

|

|

|

|

|

|

|

| The nature of resisting chemistry |

120 |

250 |

240 |

150 |

120 |

280 |

120 |

150 |

| The nature of resisting oil |

|

|

|

|

|

|

|

X |

| The nature of densify water |

|

X |

|

|

|

|

|

|

| The nature of densify water |

-40 |

-60 |

-40 |

-40 |

-55 |

-100 |

-40 |

-20 |

| The nature of resisting cold |

|

X |

|

|

|

|

|

|

| The nature of resisting milling |

|

|

|

|

|

X | X |

|

| The nature of resisting distortion mechanical |

|

X |

|

|

|

|

|

|

| The nature of resisting acidity |

|

|

|

|

|

|

|

X |

| Tensile force intension |

|

X |

|

|

|

|

|

|

| The speciality of electric apparatus |

|

|

|

|

|

|

|

? |

| The nature of resisting water and steam |

|

|

|

|

|

|

|

X |

| The nature of resisting burning | X |

|

|

X |

|

|

|

X |

| The deposited time(year) | 5-10Y | ABT 20Y | ABT 20Y | 5-10Y | 5-10Y | ABT 20Y | ABT 20Y | ABT 20Y |

More informations, please click the "PDF" download or contact with us.

Click here to download the Kaxite rubber gasket product guide pdf.